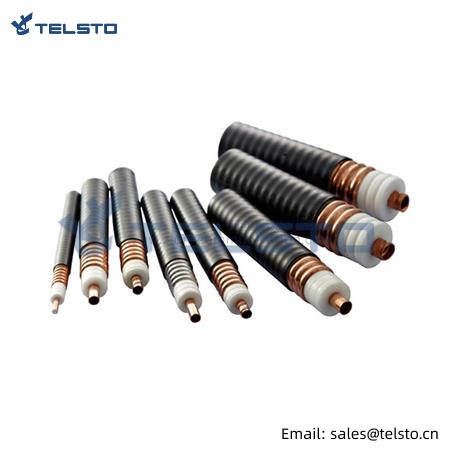

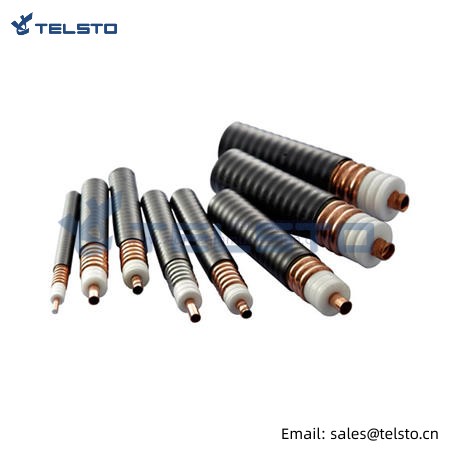

Ultra Luv Low Flexible 50 Ohms RF 5012S Coaxial cable

| Kev tsa tsev | |||

| Sab hauv tus neeg kos npe | khoom | Tooj liab Clad Txhuas Hlau | |

| Dia. | 3.55 ± 0.04 hli | ||

| kev rwb thaiv tsev | khoom | lub cev foised pe | |

| Dia. | 9.20 ± 0.20 hli | ||

| Sab Nraud Tus Thawj Coj | khoom | Helical corrugated tooj liab | |

| qhov dav | 12.00 ± 0.20 hli | ||

| lub tsho loj | khoom | PVC lossis Hluav Taws Kub Retardant Pe | |

| qhov dav | 13.60 ± 0.20 hli | ||

| Cov Khoom Siv Neeg Kho Tshuab | |||

| Dabtsi yog khoov Radius | ib leeg pheej dua tsiv | 25 hli 30 hli 200 hli | |

| rub lub zog | 800 n | ||

| NKAWM TXWV | 1.9 kg / hli | ||

| Pom zoo qhov kub | Pe lub tsho | lub lab | -70 ± 85 ° C |

| kev muab cia | -40 ± 60 ° C | ||

| kev phais | -55 ± 85 ° C | ||

| Hluav Taws Retardant Pe Tsho | lub lab | -30 ± 80 ° C | |

| kev muab cia | -25 ° C | ||

| kev phais | -30 ± 80 ° C | ||

| Cov Khoom Siv Hluav Taws Xob | |||

| kev yuam | 50 ± 2 ω | ||

| tshuaj | 82 pf / m | ||

| Inductance | 0.205 uh / m | ||

| Kev Tshaj Tawm Kev Tawm Tsam | 81 | ||

| DC rhuav tshem voltage | 2.5 | ||

| Rwb Cevhij Kuj | > 5000 | ||

| ncov hwj chim | 15.6 | ||

| Kev Ntsuam Xyuas Haujlwm | > 120 | ||

| txiav-tawm zaus | 10.2 | ||

| attenuation thiab nruab nrab fais fab | |||

| Zaus, MHz | Fais Fab Npaum @ 20 ° C, KW | nom.attenued @ 20 ° C, DB / 100M | |

| 10 | 10.1 | 1.04 | |

| 100 | 3.08 | 3.41 | |

| 450 | 1.38 | 7.59 | |

| 690 | 1.158 | 9.58 | |

| 800 | 1.01 | 10.40 | |

| 900 | 0.943 | 11.20 | |

| 1000 | 0.889 | 11.80 | |

| 1800 | 0.634 | 16.60 | |

| 2000 | 0.597 | 17.60 | |

| 2200 | 0.566 | 18.61 | |

| 2400 | 0.539 | 19.59 | |

| 2500 | 0.529 | 20.07 | |

| 3100 | 0.518 | 20.55 | |

| 2700 | 0.507 | 21.0 | |

| 3000 | 0.469 | 40 | |

| Tus nqi siab tshaj plaws yuav yog 105% ntawm cov nqi nominal li cas. | |||

| vwstr | |||

| 820-960MHz | ≤1.15 | ||

| 1700-2200MHz | ≤1.15 | ||

| 2300-2400mHz | ≤1.15 | ||

| tus qauv | |||

| 2011/65 / EU | ua raws li | ||

| Iec6119611-2005 | ua raws li | ||

Kev Siv Khoom Siv

Cov lus qhia kev teeb tsa ntawm N lossis 7/16 lossis 4310 1/2 "Kev Sib Cuag Loj Cable

Tus qauv ntawm txuas: (Fig1)

A. Pem hauv ntej txiv ntoo

B. Rov qab txiv ntseej

C. Gasket

Stripping qhov ntev yog raws li qhia los ntawm daim duab (FIGH2), mloog yuav tsum tau them thaum stripping:

1. Qhov kawg ntawm sab hauv tus neeg xyuas coj yuav tsum tau ua chamfered.

2. Tshem tawm impurities xws li tooj liab nplai thiab burr nyob rau qhov kawg ntawm lub cable.

Sib dhos cov sib khi: Ntsia thawv rau kev sib khi hauv raws cov neeg xyuas kev coj ua ntawm daim duab (Fig3).

Sib dhos cov txiv ntoo rov qab (fig3).

Ua ke pem hauv ntej thiab nram qab txiv ntseej los ntawm screwing raws li qhia los ntawm daim duab (figs (5)

1. Ua ntej ntsia hlau, smear ib txheej ntawm cov roj raj ntawm cov roj ntawm O-Ring.

2. Khaws lub nraub qaum thiab cable txav tsis txav chaw, ntsia hlau rau ntawm lub plhaub loj ntawm lub plhaub lub cev. Ntsia thawv rau sab lub cev lub cev ntawm lub plhaub rov qab siv lub duav liab. Sib dhos ua tiav lawm.